Insight Centerpoint™ Ensures Consistent Weld Quality

Insight Centerpoint is the real-time welder feedback solution that provides arc data monitoring, guidance and control within the weld cell.

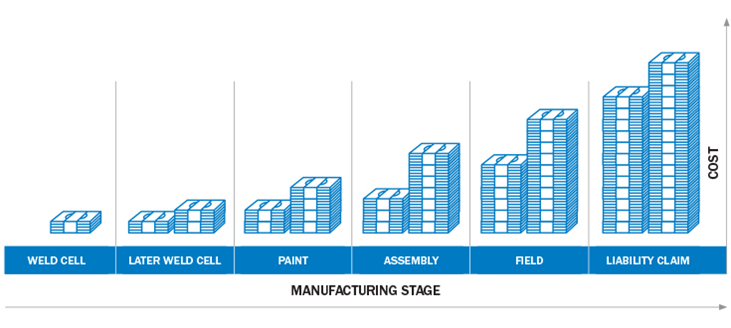

Cost of a Missed Weld or Defect

- Reduce training time. Guide welders through the weld sequence in real time.

- Ensure quality welds. Contain weld defects early and control your weld operation by monitoring every parameter of every weld.

- Reduce costs. Alert welders if a weld is missed or is outside of acceptable parameters, allowing it to be corrected cost-effectively.

Part Tracking™: Give welders complete control, from the first weld to the last

Guide welders through the weld sequence in real time using visualizations of the part. Contain missing and incomplete welds while supporting manual welding best practices.

WorkFlow™: Give welders clear, complete guidance in fabricating

Gain additional control of your fabrication process with documentation and instructional aids for pre-welding, intra-weld and post-welding activities through embedded videos, images, audio and other file types.

Integrated reports: Get immediate access to extensive information

Review a wide range of information — including preconfigured management charts and reports about weld processes, productivity and business metrics. This information is stored in an SQL server database, which contains welding data from multiple Insight Centerpoint sources.

Local/network deployment with Insight Centerpoint™

Get a graphical HMI monitor in each weld cell to provide instant feedback and assistance to the welder.

Centerpoint™ Basic vs. Centerpoint™ Premium Mode

Two modes of Insight Centerpoint are available so you can select the one that best meets your operation’s needs. Compare the features below to decide which mode of Insight Centerpoint is right for you. (The mode of Centerpoint is determined by a capability key. Each Deltaweld system requires a capability key. There are two options available, a purchased Premium key or Basic key at no additional cost.)

|

Feature

|

Basic

|

Premium

|

|

Data Storage

|

On Premises |

On Premises |

|

Networking

|

Internal Network |

Internal Network |

Communications

|

*Wi-Fi or Wired |

Wired |

|

Application Type

|

Microsoft Windows |

Microsoft Windows |

|

Scalable

|

X |

X |

|

Enterprise Integration

|

MQTT or SQL

|

MQTT or SQL |

|

Data Annotation

|

|

Time/Date

|

X

|

X |

|

Station

|

X

|

X |

|

Operator

|

X

|

X |

|

Weld

|

X

|

X |

|

Job

|

X

|

X |

|

Part

|

—

|

X |

|

Productivity/Utilization

|

X

|

X |

|

Weld Sequence Governance

|

—

|

X |

|

Process Control

|

—

|

X |

|

Reporting

|

Intra-App/Browser

|

Intra-App/Browser |

|

Data Fidelity

|

10 Hz

|

Up To 10 kHz |

* Wi-Fi is supported for Deltawelds only

Leverage Existing Investments

You don't need to invest in a fleet of new welding power sources to get the arc data monitoring benefits of Insight Centerpoint. With an ArcAgent™ module, you can have the power of Insight Centerpoint on any machine from any manufacturer.