Learning to TIG aluminum

TIG welding aluminum doesn’t need to be intimidating. With a little practice — and some basic best practices to help beginning welders — you can produce the results you want.

Follow our four steps below to practice and advance your TIG welding skills with aluminum.

Step 1: Watch hand and torch placement

Beginning TIG welders often unintentionally produce a lot of scrap because they don’t practice basic hand placement and control before striking an arc on the base material. Aluminum acts like a big heat sink and rapidly transfers heat away from the weld area, which makes puddle control crucial to success.

Hand and torch placement are key to puddle control, so it’s important to master torch and hand positioning first. Skipping this step often results in wasting good aluminum.

- Hold the torch by bracing it with the base of your hand (from your wrist to the tip or your pinky finger) flat against the table.

- Keep the torch in a steady, forward-moving position with a slight backward tilt of 5 to 15 degrees.

- Keep a close distance from the tungsten to the workpiece, typically equal to the diameter of the tungsten up to about 1/4 inch. If you pull the tungsten too far away from the workpiece, the arc spreads out too wide and overheats the piece, causing loss of puddle control.

Step 2: Coordinate movement and filler deposition

Next, you should work on the flow of your hand and torch movement without striking an arc. Practice with gloves on as you would in a normal welding situation.

Keep light pressure on your hand and a firm grip of the welding torch and slide your hand across the welding table in an even, steady motion. If you don’t move your hand and you just move your fingers, you’ve become a 1- or 2-inch welder, and there aren’t many applications where that is useful. This practice helps you calibrate hand/torch movement and the distance of the tungsten to the workpiece without creating any scrap.

Filler metal deposition takes place ahead of the TIG torch as you push forward. The torch and the filler rod should roughly be in a 90-degree configuration to each other. Always push a torch — never drag it — and always introduce the filler metal on the leading edge of the puddle. One hand is smooth and steady as it slides, while the other hand dabs the filler metal. Practice this without striking an arc.

Most beginners have issues at first with getting their hands to work independently and often end up moving both hands at the same time. As they attempt to dab the filler metal, the tungsten dips too, which usually results in touching the filler metal to the tungsten and contaminating it.

Practice will help you get to where each hand performs its task independently. When you’ve mastered these movements, you’re ready to strike an arc.

Step 3: Practice puddle control

Using the tips previously discussed about proper hand and torch placement — and without adding any filler metal — establish the puddle and walk it down the workpiece.

Because aluminum is a heat sink it gets hot quickly. Like driving a car downhill, it picks up speed as it gets hotter. This makes it important to monitor the puddle as you move along in order to keep the puddle width consistent. If the puddle gets too hot, ease up on the foot pedal to maintain a consistent width.

When you get to the edge of the workpiece, where there is less aluminum to absorb heat, the base material gets hot quickly and the puddle washes out much faster. It’s important to ease up on the pedal to maintain puddle control. However, if you don’t put enough heat into the puddle, the puddle will disappear, the arc will become erratic and you’ll do nothing more than etch the aluminum.

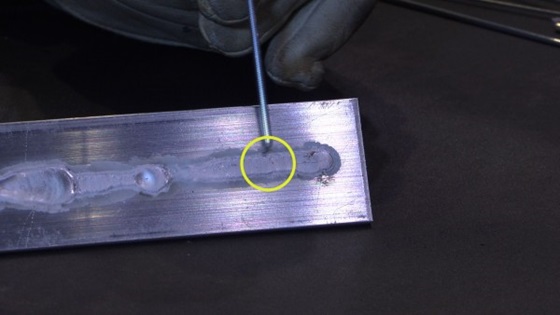

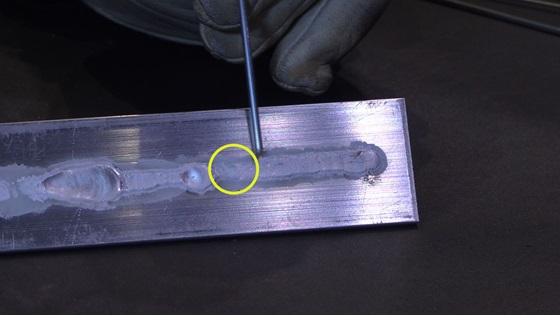

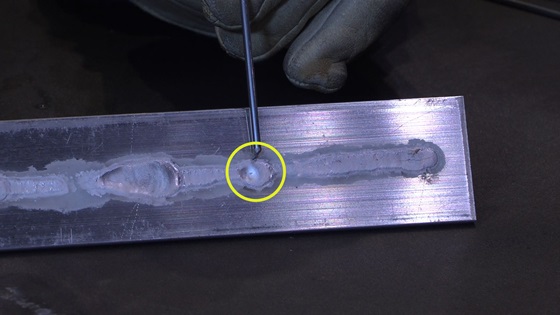

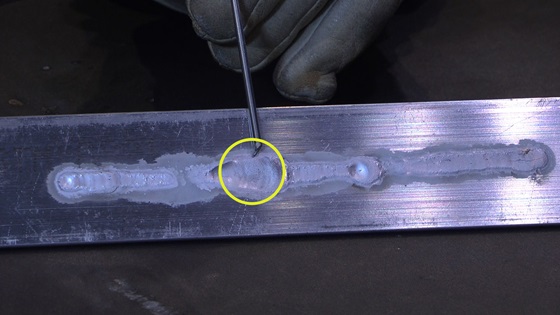

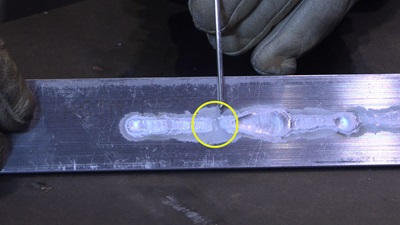

The following sequence of photos shows how speed and heat affect the puddle:

Lay down a puddle like this without filler metal numerous times to practice maintaining speed, distance and puddle width. Because the piece gets hot so quickly, set it aside and pick up another one before continuing. The hotter the piece gets, the more out-of-control the puddle becomes, which makes training difficult.

Fig. 1: Proper puddle width, maintaining speed and distance between the tungsten and the workpiece.

Fig. 2: Moving the torch too quickly along the piece causes you to lose puddle control. Slow down while maintaining heat input.

Fig. 3: Slowing down torch speed too much and adding too much heat to the puddle causes problems related to excess heat input, as seen in the weld here.

Fig. 4: Even with proper speed, adding too much heat to the puddle causes you to lose control of the puddle, as seen here. Find the balance between speed and heat input.

Fig. 5: Proper torch speed, but not enough heat put into the workpiece causes the puddle to disappear.

Lay down a puddle like this without filler metal numerous times to practice maintaining speed, distance and puddle width. Because the piece gets hot so quickly, set it aside and pick up another one before continuing. The hotter the piece gets, the more out-of-control the puddle becomes, which makes training difficult.

Step 4: Introduce filler metal to the puddle

Keeping in mind the details discussed in step 2 above about filler metal deposition, you’re ready to introduce filler metal to the puddle.

The key to adding filler metal to the puddle is consistency. Start introducing the filler metal with a dab and move motion. There is no need for excessive torch movements, as the dabbing of the filler metal creates the bead profile.

Establish the puddle and add filler metal to the edge of the puddle. As you establish the movement, you can also establish your rhythm. As long as you maintain a consistent rhythm combined with steady torch movement and puddle control, you’ll be laying a proper weld bead on aluminum in no time.

Step 5: Setting weld parameters/understanding advanced features

Some TIG machines allow you to fine-tune your TIG welding arc to better match the joint design or tailor the weld bead appearance to your preference. Besides setting just the amperage based on material thickness, fine-tuning can be done by adjusting balance and frequency.

The balance function controls the cleaning, or etching, of the oxide layer off of the aluminum so it can be properly welded without puddle contamination. The lower the balance number, the more cleaning you get, and the higher the number, the less cleaning you get. You might want to change this setting based on your joint design, how heavy the oxide layer is on the aluminum or the desired look of the finished weld bead.

The frequency function focuses the arc, and this setting is useful to tailor your arc based on the joint design. The lower the frequency setting, the wider and lazier the arc is. The higher the setting, the tighter and more focused the arc becomes. Higher frequency settings are helpful when welding in tight areas or where more precision is needed. Lower settings give you a wider, flatter bead that is good for butt joints or areas that need to be built up with weld material.

It’s a good idea to practice with adjusting these settings to see how they can fit your needs and preferences.

Taking it slow — and taking the time to practice — can help you reduce aluminum scrap and build your skills as you learn to TIG weld aluminum.