Tungsten electrodes for welding

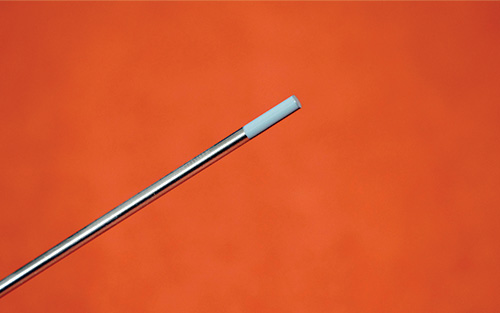

One of the reasons TIG welding is favored for sensitive welding applications is because it gives the welder superlative control. The heat for welding comes from an electric arc that streams from a tungsten electrode in the torch. Over the years, welding engineers have found many ways to tailor these electrodes for specific applications by adding small amounts of exotic elements to the tungsten. The different types of electrodes are identified by a band of color at one end.

In the early days of TIG welding there were only two types of tungsten that were commonly used. Pure tungsten was favored for aluminum and magnesium, and 2% thoriated tungsten was used for everything else. While these worked well for generations, research and development led to a broad range of tungsten electrodes, each with unique properties. It can be somewhat bewildering for a beginning welder to sort through all the options, so we’ll take a look at the most widely used types of tungsten electrodes. This should help you make an informed decision about which one is best for your welding projects.

Pure tungsten was used as a welding electrode at the beginning of the TIG process, back in the 1940s. TIG welding was developed to efficiently join aluminum and magnesium alloys, and pure tungsten made sense at the time, since it has the highest melting temperature of all metals. In those days power sources were transformer based, and pure tungsten could accommodate welding in the AC mode, which is the standard for aluminum and magnesium. Back then, it was common practice to prepare the tungsten by “balling” the tip. This was done by briefly running a burst of current through the electrode with the power source set to the “reverse polarity” (electrode positive) mode. This would melt the tip of the electrode, and when the current was terminated the tungsten would solidify into a smooth, shiny ball. The shielding gas prevented the electrode from oxidizing, and the size of the ball could be controlled by the amount of current that was run through the electrode in the EP mode. This balled electrode would shape the arc into a wide cone, and the electrode could carry fairly high current without “spitting,” or transferring tiny amounts of tungsten into the weld puddle. Note that with modern inverter power sources, pure tungsten electrodes are not recommended.

For DC welding (used for all metals other than aluminum and magnesium) a small amount of thorium was added to the tungsten electrode, usually 2%. This made arc starts more consistent, and increased the current carrying capacity of the electrode.

Even though these two types of electrodes handled the needs of TIG welders for decades, they are not commonly used with modern welding equipment, for some good reasons. When the industry migrated from transformer to inverter power sources, balling the electrode for AC welding was no longer required, and pure tungsten electrodes gave way to superior blends.

Thorium is slightly radioactive and handling thoriated tungsten electrodes poses health and environmental risks at elevated exposure levels. Consult the AWS Safety and Health Fact Sheet on Thoriated Tungsten Electrodes for more information.

Other elements have proven to be superior to thorium for electrodes in every way. As you’ll see, there are a couple types of tungsten electrodes that are well suited for virtually any TIG welding task, either AC or DC

2% lanthanated tungsten (color-coded blue) is at the top of the list. This is a true all-purpose electrode, with excellent arc starting characteristics and the ability to transmit high current without spitting. It provides a stable arc at both high and low current, and works very well on all metals.

2% Ceriated tungsten (grey) is another good choice for all types of welding; providing good arc start and restart characteristics with no spitting. It is ideal for low- and medium-current welding on all metals.

Rare earth tungsten (chartreuse) has the very best low-current arc starting characteristics, and it can be used on all metals. This type is often preferred for automated welding.

Zirconiated tungsten (white) is good for welding aluminum and magnesium alloys. It has high current-carrying capacity, and it provides better arc starts and stability than pure tungsten.

Tungsten electrodes come in a wide range of diameters — from .020-inch diameter up to ¼-inch. You need to select a diameter large enough to accommodate the maximum current used for each welding job. Smaller diameter electrodes will start the arc more readily at very low amperage settings. For the work I do, which involves a broad range of shapes and sizes, I use a 3/32-inch diameter electrode. I have no problem with arc starts, even for light-gauge sheet metal, and I can weld metals ¼-inch thick, or more.

The most common length for tungsten electrodes is 7 inches. For working in restricted areas, it may be beneficial to cut them down, allowing a shorter back cap to be used on the torch.

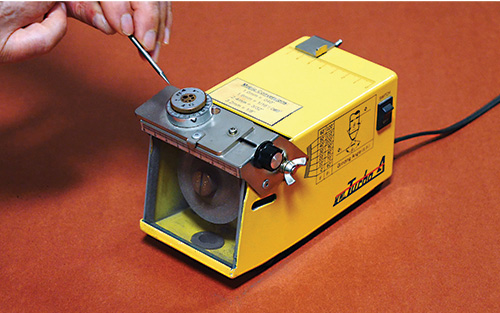

Tungsten can be cut with an abrasive cutoff wheel or ground through with the corner of a grinding wheel. Do not cut the electrodes with a wire cutter or break them by bending. This may result in unseen fractures at the cut ends, which can cause an erratic arc.

Tungsten electrodes usually come with blunt ends that need to be sharpened before use. The angle of the point determines the shape of the arc that streams from the electrode. There is an inverse relationship between the electrode point angle and the arc — a sharply pointed electrode will produce a cone-shaped arc with a broad base where it hits the metal, creating a wide puddle. This can be beneficial for edge-welding thin materials.

Conversely, a stubby point on your tungsten will produce a narrow cone with a small base, focusing the energy into a smaller area. This can help you get deep penetration on thicker materials. With some experimentation, you can find the point angle that gives you the characteristics best suited for a particular job.

For very high-amperage welding, it can help to grind a small flat at the tip of the tungsten electrode. This will help prevent the electrode from spitting small particles into the workpiece.

There are lots of tools made specifically for sharpening tungsten electrodes, but you can do a good job with a stone, belt or disc grinder. To avoid contaminating the electrode, use a dedicated grinder for tungsten, and be sure that all of the grinding scratches are parallel with the electrode centerline. If you leave angled or spiral grinding scratches, the arc may be unstable.

It is not uncommon for electrodes to get contaminated. This can happen when the tip is accidentally touched to the molten puddle, or if the filler rod contacts the hot electrode. Sometimes impurities in or on the metal can fly out and contaminate the electrode, too. It is essential that the electrode be absolutely free from any contamination, so be ready to swap it out whenever this happens. It can help to have several pre-sharpened electrodes handy as you weld.

Even though there are many choices for tungsten welding electrodes, after you have selected an appropriate type and diameter for your application, you shouldn’t have to think much about it. A good all-purpose electrode, like a 3/32-inch diameter, 2% lanthanated, should be an excellent choice for most welders.