Spool gun welding on aluminum

MIG is the most common welding processes for hobbyists, and it’s a mainstay for commercial fabrication and repair facilities. Steel is the most used metal for welding because it’s strong, inexpensive and suitable for most fabrication processes. Aluminum is probably the second most widely used material, and it can reduce weight while maintaining good strength and workability. Aluminum is steadily taking a greater role in transportation industries, since “adding lightness” is essential for making vehicles more fuel-efficient and for getting more range from battery power. Most welders TIG weld on aluminum, but not everyone knows that even affordable MIG welders like the Millermatic® 211 can weld aluminum.

MIG machines usually house a wire spool inside the case, which is fed through the gun cable to the weld. This delivery system works well for steel, but it is problematic for the softer aluminum wire. This wire can sometimes bind; especially when being pushed through a long cable that is draped over obstacles.

There is an easy solution for this issue — using a spool gun. This type of gun holds a spool of wire so the feed path is short and straight. The Miller® Spoolmate™ 150 Spool Gun is a direct replacement for the gun on the Millermatic 211, and requires no tools for installation.

Pure argon gas is required to MIG weld aluminum — not an argon and CO2 mixture commonly used for welding steel. You can use the same regulator or flowmeter that is used with the C-25 gas.

With the spool gun installed, load your spool, connect your gas, and you’re ready to dial in the settings. The Spoolmate 150 integrates with the Auto-Set™ feature on the Millermatic 211, so you can start simply by dialing in the material thickness and the wire diameter.

Welders commonly use a short-circuit arc to weld aluminum, which produces the familiar “frying bacon” sound. Aluminum welding with a spool gun utilizes the much faster spray transfer mode. This may take some getting used to, since you’ll need to move the gun quickly to keep up with the process.

You should always use a push technique with the spool gun. Use a 20-degree work angle to ensure the shielding gas can keep the atmosphere away from the weld zone. Laying the gun down flatter may compromise the gas coverage at the weld. You will have to experiment to find the proper gas flow, but 35 CFH is a good place to start. Insufficient gas flow can cause heavy black soot to form around the weld area. It’s very important to have sufficient wire “stick-out” when welding aluminum — 3/4 inch is recommended. If your stick-out is too short, the wire may burn back and foul the contact tip.

While the Auto-Set feature works with the spool gun, I have found that minor adjustments to the wire feed speed and voltage can help achieve ideal penetration and bead contour and minimize the formation of soot in the weld area. Find the recommended settings inside the machine’s cover; they are a good starting point for adjustments you want to make.

You can easily adjust the settings for wire feed speed and voltage with the dials on the machine’s front panel.

Cleanliness is important with any welding process, but aluminum is particularly intolerant of any surface contamination. The best practice is to first use a degreaser to remove any oily contaminants on the metal. Then, carefully scrub the weld area with a dedicated stainless steel wire brush just before welding.

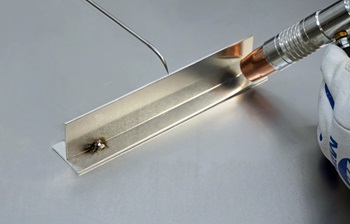

The first trial I did with the Spoolmate 150 gun was a fillet weld on 0.080-inch aluminum sheet, using 0.030-inch 4043 wire. I temporarily held the parts in the proper alignment and tack welded them together.

After several tests, I got the best results with wire speed at 5 and voltage at 60, using 30 CFH gas flow. The best gun angle was 45 degrees from each side of the joint, with a 20-degree travel angle. I experimented with moving the gun faster and slower until I found the speed that gave me the best bead profile.

You will often see a little black soot develop at the edges of an aluminum MIG weld. However, it was minimal at these settings. I removed the little soot left with one or two swipes of a wire brush.

Next I set up a lap joint on 3/16-inch plate. I did a few tests to find the settings and travel speed that would produce a bead that filled the step completely and leave a nicely rounded bead profile. I held the gun at 45 degrees from the work and used a 20-degree travel angle.

The next test I did was a corner weld on 1/4-inch aluminum plate. Fixturing the plates corner to corner, 90 degrees to each other, automatically created a small trough. I held the torch vertically while using a 20-degree travel angle. I also experimented with different travel speeds until I found what worked best. In the end, I got a nicely rounded weld bead that just filled the trough.

The spool gun works well for welding aluminum castings, too. I happened to have some cast components of a motorcycle oil tank, and I welded two sections together, getting a nice clean joint.

All in all, I found the Spoolmate 150 spool gun quite easy to set up and use. The process is similar to using a traditional MIG gun, but aluminum has some unique properties that you’ll appreciate. Miller makes other spool guns, including the less expensive Spoolmate 100 — but it has a shorter cable and a lower duty cycle and is only recommended for 4000 Series wire. The Spoolmate 150 works with both 4000 and 5000 series wire, and it’s a better choice if you need high output capacity.

The Spoolmate 150 works with several Miller welding machines, but you can explore all its features with the Millermatic 211 — a very light and compact MIG machine. The 211 can also run on either 120 or 240 volts by simply swapping ends on the multi-voltage plug (MVP™).