Understanding AC Balance Control on Miller® TIG Welders

Print Article

Learn more about the benefits of adjustable AC TIG balance control found on Miller TIG welders and how to use this feature.

Improve TIG welds with AC balance control

TIG welding certain materials, like aluminum, requires attention to many details to produce high-quality results. For operators who want more control in their TIG welding arc, there is a machine feature that can help.

Squarewave alternating current (AC) output with balance control is a feature on TIG welders that helps operators keep their welds consistent.

Learn more about AC balance control for TIG and how it helps improve your welds.

What is AC balance control?

To understand how balance control works, it’s important to first understand why certain materials, such as aluminum and magnesium, require an AC welding output.

When aluminum is exposed to air, it forms an oxide layer that melts at a much higher temperature than the base material does. Aluminum oxide typically melts at 3,600 degrees Fahrenheit, while aluminum melts at 1,200 degrees. This oxide layer can inhibit proper weld fusion and puddle fluidity if it’s not removed prior to welding.

However, the squarewave alternating current (see Fig. 1) inherently provides a cleaning action (see Fig. 2) that helps remove this oxide layer. The electrode positive (EP) portion of the AC

cycle — where the current flows from the work to the electrode — actually blasts off surface oxides.

Fig. 1. AC current is used to weld aluminum because its positive half cycle provides a "cleaning" action and its negative half cycle provides penetration.

This then allows the electrode negative (EN) portion of the cycle — where the current flows from the tungsten into the workpiece — to melt the base metal and fuse the joint.

Fig. 2. Notice the lighter colored "etched zone" or "cleaning action" created by the AC arc.

Balance control ranges

Until balance control was introduced on Miller TIG welders, the amount of EP (sometimes referred to as the cleaning action) and the amount of EN (sometimes called the weld penetration action) was balanced at 50/50. But this generalized, one-size-fits-all approach doesn’t provide the ideal arc for all TIG applications. For example, snowmobile heat exchangers, trailers or boat lifts that have been in service will have heavier oxides and require more cleaning and oxide

removal when welding compared to new material.

The balance control feature allows operators to tailor the TIG arc for each job.

With transformer-based TIG welders, operators could set balance control on a range from 0 to 10 — from maximum cleaning to minimum cleaning. This correlates to an EN portion of the AC cycle from 45% to 68%. In other words, 68% of the AC cycle (which is 1/60 of a second) is spent putting energy into the workpiece.

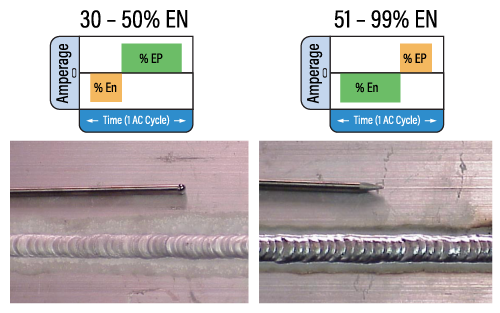

Modern inverter-based Syncrowave® machines have a balance control setting of 60-80% EN, while Dynasty® TIG welders extend balance control even more, allowing EN duration times from 30-99%.

Fig. 3. A comparison between greater (top) and lesser (bottom) amounts of EN.

Benefits of AC balance control

The ability to adjust and tailor the EN cycle can affect the weld bead performance and appearance.

By making the EN portion of the AC cycle last longer, operators see these benefits:

● Oxide removal with a secondary characteristic of tungsten geometry.

● Possibility of increased travel speeds.

● Increased tungsten electrode life and reduced balling action.

● Ability to use a smaller-diameter tungsten to more precisely direct the heat or make a narrower weld bead.

● Reduced size of the etched zone for improved weld appearance (see Fig. 3).

Reducing the EN portion of the cycle provides these benefits:

● Greater cleaning action to remove heavier oxidation.

Keep in mind that a reduced EN portion of the AC cycle does decrease tungsten life and increase balling action.

How to use balance control

There are no hard rules about setting balance control, though operators commonly will set either too much cleaning or not enough cleaning.

Too much cleaning action (EP duration) causes excess heat build-up on the tungsten. This creates a large ball on the end of the tungsten. As a result, the arc is less stable and the operator loses the ability to control arc and weld puddle direction. Arc starts will also begin to degrade.

Insufficient cleaning action — or too much EN time — results in a scummy weld puddle. If the puddle looks like it has black pepper flakes floating on it, add more cleaning action to blast away oxides and other impurities.

For modern inverter-based machines like Syncrowave or Dynasty welders used on clean aluminum, a good starting point is setting the EN between 68-75%. It’s a good idea to complete

practice welds on scrap pieces before welding to determine the best balance control settings.

Use balance control to optimize TIG welds

Balance control is a feature that can help you keep your TIG welds consistent no matter the application. For welders new to using balance control, it can help to note the results seen when welding with different material types and thicknesses, along with the weld parameter settings that were used to produce those results. Learning to properly adjust balance control can help deliver the high-quality TIG welds you want.