The Most Common MIG Weld Defects on Aluminum and Steel and How to Avoid Them

Print Article

This article describes some of the most common MIG welding defects and how to identify them by weld bead appearance.

MIG welding defects

Some of the most common weld defects are porosity, lack of fusion and burn through. Aluminum often presents a few more welding challenges than steel. Aluminum conducts heat about six times faster than steel, has excellent thermal conductivity, and has a low melting point, making it extremely susceptible to warping and burn-through. Additionally, aluminum wire has less tensile strength, which can pose wire feeding issues and lead to weld defects if not using the correct equipment. We’ll highlight the differences here.

Porosity

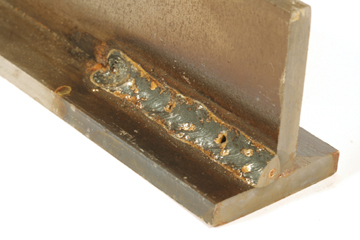

Shielding gas protects the molten weld pool from the surrounding atmosphere, which would otherwise contaminate the weld. Figure 1 shows how the lack of shielding gas on steel can cause porosity. Porosity is when pinholes form in the weld bead face and weld interior in the absence of shielding gas. Improper equipment settings, a hole in the gun liner or wind can contribute to poor gas coverage.

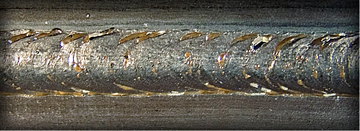

If using a drag vs. a push technique (FIG. 3, below) on aluminum, you may get a sooty looking weld (FIG.2). The soot can be removed, but cutting the weld open will reveal pinholes where impurities are trapped in the weld. Aluminum builds up an oxide that needs to be removed before welding. Wire brushing is the most common method of cleaning aluminum. Use a stainless steel brush to avoid contaminating the weld with the impurities of a steel brush.

FIG. 1. No shielding gas on steel - A lack of or inadequate shielding gas is easily identified by the porosity and (pinholes) in the face and interior of the weld.

FIG. 2

On aluminum, a sooty looking weld (FIG.2) can be caused by using a drag vs. a push technique (FIG. 3, below). The soot can be removed, but cutting the weld open will reveal pinholes where impurities are trapped in the weld. Aluminum builds up an oxide that needs to be removed before welding. Wire brushing is the most common method of cleaning aluminum, but it needs to be done with a stainless steel brush to avoid contaminating the weld with the impurities of a steel brush.

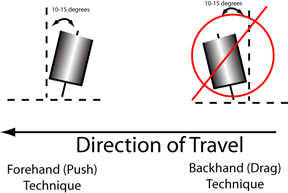

FIG. 3.

Push vs. drag technique. On steel, either pushing or dragging the gun is acceptable, but with aluminum, the drag technique will lead to weld defects.

Lack of fusion

Lack of fusion can occur when operators set voltage or wire feed speed too low, or when travel speeds are too fast. Because aluminum conducts heat much faster than steel, it is prone to lack of fusion at the start of a weld. Some welding equipment addresses this by automatically ramping up the current at the start of a weld and then decreasing it to avoid heat build up.

Craters

With aluminum, a common MIG welding defect is when craters form at the end of a weld. If operators do not fill them in, they create a stress point, which can lead to cracking. This requires the user to quickly trigger the gun again to fill in the crater. Some welding machines offer a crater timer that will fill in the crater when the operator releases the gun trigger.

Burn through

Causes of too much heat input include setting voltage or wire feed speed too high or by too slow of a travel speed. This can lead to defects like warping or burn through especially when MIG welding thinner materials. Aluminum is more prone to the effects than steel. Generally, aluminum requires a faster travel speed than steel to avoid heat build up.

Feeding aluminum

Because of its low columnar strength, feeding aluminum wire has been likened to pushing a wet noodle through a straw. “Birdnesting,” or the tangling of the wire between the drive roll and the liner is a common, time-consuming and costly problem. Clearing it requires the operator to stop welding, cut the wire, discard the wire in the gun, and refeed new wire. It also may require cleaning or changing the contact tip because of the burnback caused when the wire stops feeding.

There are several ways to feed aluminum wire: Push only, spool gun, push-pull system and continuous feed push only system.

- Push only: Feeding aluminum wire through a push only system can be difficult, but can be done on a limited basis. To avoid weld defects, use a u-groove drive roll to provide more surface contact with the wire. You’ll also need a Teflon liner, adequate drive-roll pressure, and the ability to keep the gun cable straight.

- Spool gun: A spool gun, such as the Spoolmatic® 15A or 30A, eliminates the possibility of birdnesting by putting a 4-inch (1-lb.) spool on the gun, so the wire only feeds a few inches. Spool guns can accommodate aluminum wire diameters from .023 to 1/16-inch and allow the operator to use longer cables (15′-50′). You’ll need to change the spool gun roll after every pound of wire, compared with the 8- or 15 lb spool on a push-pull system.

- Push-pull gun: With a push-pull gun, a motor in the gun pulls the wire through the liner, while the motor in the welder or feeder control becomes an assist motor. By maintaining consistent tension on the wire, the push-pull system helps eliminate birdnesting. It is more ergonomic than the spool gun, since the weight of the spool is not in the operator’s hands. Also, operators can change the spool less often than on a spool gun and allows the purchase of larger spools. However, remember that aluminum builds up an oxide layer when exposed to air for a while. If you only use a pound or two of aluminum a week, the smaller spool may be a better choice.

Choosing the right equipment

Choosing the right equipment can address many MIG welding defects before they occur. AutoSet™ technology, found on many Millermatic welders, relieves the operator of dialing in parameters when welding steel. With Auto-Set, the operator simply selects the thickness of the steel and the diameter of the wire being used, and the machine sets the optimal voltage and wire feed speed.

For welding aluminum, all Millermatic and Multimatic machines feature infinite voltage control, which allows the operator to fine tune settings. This helps avoid putting too much or too little heat into the weld. Older equipment may use tapped settings that can make it more difficult to set, especially when welding thin material.

In addition, all Millermatic and Multimatics can use spool guns to allow easy set up for both steel and aluminum welding. The Millermatic 252, 255 and Multimatic 235, 255 and 252 also features Auto Gun Detect™, so the operator only has to pick up the MIG or spool gun and pull the trigger to start welding.

The Millermatic 255 and Multimatic 255, features pulsed MIG welding, which helps eliminate burn through on thin materials. In addition, it features an XR-Aluma-Pro™ push-pull gun, which helps eliminate wire feeding issues. Additional technology, such as Aluminum Pulse Hot Start™ provides more power at the start of a weld to avoid the “cold start” to which aluminum welding is prone.

Troubleshooting MIG welding defects

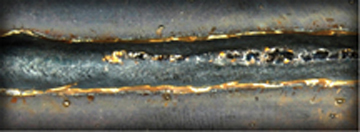

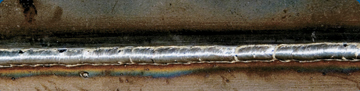

The photo above shows an example of a good weld on steel. Below are photos of a selection of MIG welding defects that can result from a variety of potential problems:

Voltage too low: Too little voltage results in poor arc starts, control and penetration. It also causes excessive spatter, a convex bead profile, and poor tie-in at the toes of the weld.

Wire feed speed/amperage too high: Setting the wire feed speed or amperage too high (depending on what type of machine you’re using) can cause poor arc starts and lead to an excessively wide weld bead, burn-through and distortion.

Wire feed speed/amperage too low: A narrow, oftentimes convex bead with poor tie-in at the toes of the weld marks insufficient amperage.

Travel speed too fast: Traveling to fast can cause a narrow convex bead with inadequate tie-in at the toes of the weld, insufficient penetration and an inconsistent weld bead.

Travel speed too slow: This may produce a large weld with excessive heat input resulting in heat distortion and possible burn through. In most cases, proper travel speed is when the arc is on the leading edge of the puddle.

Voltage too high: Too much voltage leads to poor arc control, inconsistent penetration, and a turbulent weld pool that fails to consistently penetrate the base material.

This article was originally prepared for and published in Sign Media Canada (www.signmedia.ca).