How to start a welding business.

You like welding and you’re good at it. You may even take on small welding jobs to earn some extra money. But how do you know when you’re ready to make your hobby or side gig a full-time business?

Three business owners share tips on starting a welding shop, what equipment to invest in and how to deal with customers.

- Gregg Whitehall owns Metalsmoke Design in Milwaukee. He spent 40 years in manufacturing jobs, including as a machinist, a welder and a weld supervisor. He did welding gigs on the side before starting his own full-time shop three years ago.

- Michael Brandt owns Garage Bound LLC in Chattanooga, Tenn. His background includes work as a forklift technician and an electrical technician as well as experience in metal fabrication and ornamental ironwork shops. He became interested in building rat rod bikes with his son and taught himself to weld as a hobby, which turned into a passion and his own business.

- Missy Powell owns S.M.T. Metals in Arvada, Colo. She worked in a fabrication shop and was doing welding work on the side before going full-time on her own about a year ago, specializing in custom welding fabrication and sculpture.

Q: Why did you decide to start your own business

Gregg: The side hustle started about 20 years ago, and COVID actually put me in it full-time. The company I was working for went out of business, so that was an easy decision. I already had everything set up for welding on the side. A couple of clients came to me with pretty big jobs, and I knew I could live for months off those two jobs. Honestly, I should have done it years ago. I don’t know why I waited so long.

Michael: It’s the only way I had to earn money that I really enjoyed. There are a lot of benefits to being self-employed and there’s a lot of drawbacks. It was a lot of pressure and stress, that first year in business. I started from a home garage in 2008. Now I’m in a 7,000-square-foot building.

Missy: I was ready to have more control over my schedule and to be able to see my mom and my dad more. My dad is sick, so I wanted to be able to help my mom out a little bit more.

Q: What type of welding work do you do?

Gregg: I do a lot of bar and restaurant work. Some of that is under my business, Metal Smoke Design. But I also subcontract to a lot of design firms, so I’m basically the maker’s maker. I do commercial railings, furniture, ornamental sculpture pieces, back bars. I usually do three or four jobs a week.

Michael: I take on all kinds of custom fabrication and repair work. A fab shop where I used to work, sometimes if they get a giant project with a crazy short deadline, they'll pay me my shop rate to go over there and help them, which is really cool.

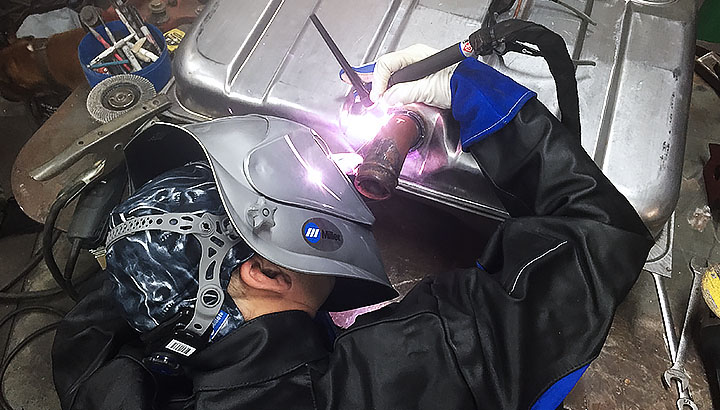

Missy: I’m pretty much a one-woman show so I can only do one project at a time but I might have four or five things on the docket lined up. TIG stainless was my bread and butter for a long time. But now that I’m full-time with my own business, I do a lot more MIG. It makes more sense for production time. I work with a lot of major construction companies and interior designers. Right now I’m doing a light fixture for one designer and a handrail and a custom wine fridge for another designer. We often sit down and come up with ideas together.

Q: What are some of the challenges of running your own shop?

Gregg: There is the whole right brain, left brain thing of running a business. I’m not an accountant. But the industrial park where I’m located is very helpful to small businesses. They offer accounting services and training, which is great.

Michael: Dealing with employees is the hardest for me. I’ve learned over time that the best way to be a business owner is to have somebody between you and your employees as far as running the crew. The first year I had six employees and I learned with that many employees, you have to take every single job coming through just to make payroll. Another big challenge for me is my cross between work and play. I have so many hobby interests that they cross over, so it’s not always just business. I think my build partner and I have 15 vehicles right now ready for work.

Missy: The biggest challenges for me are things on the business side. I spent 10 years learning to be a fabricator and I spent zero years learning to run a business. Handling both sides — the work in the shop and the work behind the desk — and burning the wick at both ends is challenging.

Q: What do you enjoy about owning your own business?

Gregg: I haven't woken up to an alarm clock in three years. I control my day and how slow or fast I work.

Michael: My wife loves to travel and do fun things. If I can work really hard for seven days a week for three or four weeks and save enough money to where I can take a break, and things are being handled while I’m gone, then I feel like I should be able to do that. I also bring my dogs to work every day, which is one of the coolest things.

Missy: The freedom to have more control over who I work with, who I'm around. I used to not have any control over the people I spent 80% of my life with, which can beat your soul down after a decade.

Q: What equipment did you start with?

Gregg: At my job, I had extra money withheld from every paycheck. Then when I would get my tax return, I would buy a piece of equipment for my garage with that extra money. So when I decided to start this business, I had all my welding equipment. I have a TIG welder and a Multimatic® welder. When I started full-time, I did buy a CNC table. If you do it right, the CNC table does the work of a couple people.

Michael: When I started out, I had a Millermatic® 185 and a Syncrowave® 250 TIG welder. I had a handheld plasma cutter and grinders. I had a milling machine and a lathe. You have to figure out if you’re going to be a shop or if you’re going to be mobile because it will require different equipment.

Missy: I had my Multimatic 215 that I bought when I was still in my apprenticeship. I pretty much run my entire business off that machine.

Q: What tips would you give others thinking about striking out on their own?

Gregg: Getting a customer base is important, and your location has a lot to do with it. I’m the only welder in this industrial park, and these commercial companies will come to me — I get work and don’t even have to leave. Don’t be reliant on any one industry. Diversify your customer base.

Michael: I’m self-taught for the most part, but I did know people who were very knowledgeable. Find mentors in your industry, in your local market where you plan on operating. Then start by buying and learning how to use all the equipment that you need and having a place to store that equipment safely. Number two is your skillset. Don’t ever overpromise. Be cautious about the jobs you take to make sure they match your current skillset and your machine’s capabilities.

Missy: Take a business class. If you think you can weld and you want to start your own business, you’ve got to be able to run the business too. It’s a constant balance. I usually start and end my day doing office stuff.

Q: How do you differentiate yourself from competitors?

Gregg: I am diverse in my background. I am a toolmaker, I’ve got experience in welding, I’ve been on the design side, so I can talk with machinists, I can talk with engineers, I can talk with architects. I’ve also learned to be quick and have really fast turnarounds. With the bar and restaurant industry, especially the new construction bar industry, everything's behind schedule. I make myself available, stay there until the job's done, then be there so everything goes smoothly. Also, quality is key. Everyone compliments me on my work.

Michael: One thing that differentiates me is my aluminum mobile welding capabilities. I have a Dynasty® 400 that I power off a Bobcat™ engine drive, so that gives me an advantage because I can TIG weld up to ¾ inch. We do a lot of aluminum TIG welding in the field. Another thing is the specialized equipment in my shop I’ve invested in. I have a radius rolling machine, a plate roller, a CNC plasma table and tubing bender. Those things have brought me a lot of business.

Missy: I have a very detail-oriented approach. I put a lot of energy into making sure it’s absolutely perfect. Also, when a customer calls, it’s my cell phone and they always get me. Pretty much my entire business is word of mouth, so I cannot have something go wrong. I just make sure the customer is happy.

Q: How do you find work?

Gregg: Everything has been word of mouth. I’ve built a customer base that is probably 80% repeat industrial customers. These are bar/restaurant groups that own three, four or five bars and restaurants, and they have a constant flow of projects. Now I only take on the higher-profile jobs. Being the maker’s maker and going through the back door to get work for these industrial and commercial businesses is just more efficient. When I get new commercial business, it’s often people who are checking out the new thing and they’ll ask, “who made that?” That spawns the next big commercial job for me.

Michael: All my business is repeat business, word of mouth and referrals. That’s why it’s so important to keep customers happy. And if you’ve paid us and something isn’t right, we drop everything to make sure to correct it and keep you happy. I go the extra mile even if it costs me money, time or materials.

Missy: I’m really passionate about it and I'm also extroverted, so I'm able to hustle and find work by just talking to people. Then that leads to them telling someone else about me or someone will see me welding and it snowballs. Especially if people like what you do and you do a really good job for them, it ends up creating its own little path that starts branching out to all these little fingers everywhere.