Weld data monitoring options

When it’s time to choose a solution, there are several options available, ranging from basic to more advanced.

Insight Core™ weld data monitoring

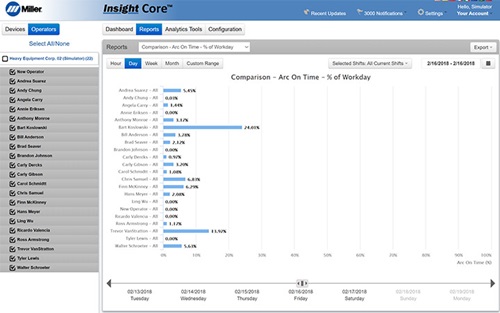

Insight Core is a cloud-based weld data management solution. It is designed to monitor and report welding productivity with a goal of improving arc-on time and filler metal deposition rates. Think of Insight Core as a manager's tool for passive monitoring of a welding operation.

Insight Core allows you to:

- Measure welding productivity. Operations can see each welder’s arc-on time, which can be used to set baselines, plan improvements and measure progress toward goals.

- View easy-to-understand reports. Data that’s hard to analyze can hide important facts about your welding operation. Insight Core dashboards allow operations to identify important trends and develop reports with data that can be analyzed for action. Use the data to evaluate comparisons between operators, weld cells, and physical plant locations. Core can report these trends by day, week, month, shift and more.

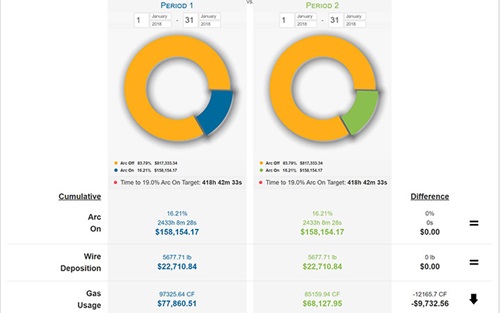

- Identify welding costs. Not knowing true welding costs keeps operations from realizing where costs can be lowered. Insight Core helps you identify the costs in the welding operation, so you can make improvements that reduce expenses.

- Install and use easily. Insight Core only requires an internet connection to gather data. Secure data is viewable from anywhere on any web-connected device.

Multiple levels of customizable dashboards provide an at-a-glance view of performance. The system provides vital facts about the machines in operation, including:

- Amperage and volts

- Arc-on time and arc starts

- Weld deposition amounts

In addition to helping identify and track production goals as part of continuous improvement initiatives, the dashboards can collectively help companies assess their costs. They provide information to determine true welding costs, identify areas where costs could be reduced and track the outcome of cost-reduction efforts.

With powerful reporting tools that allow customized views of each of these dashboards, it’s easier for leadership to analyze the company’s productivity and goal metrics in a way that is the most intuitive to them.

Watch this video to learn more about the benefits of Insight Core technology.

Insight Centerpoint™ weld data monitoring

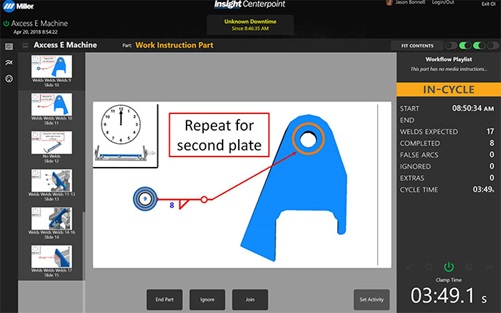

This solution provides welding operations with a real-time solution that guides welders through weld sequences, reducing training time and missed welds.

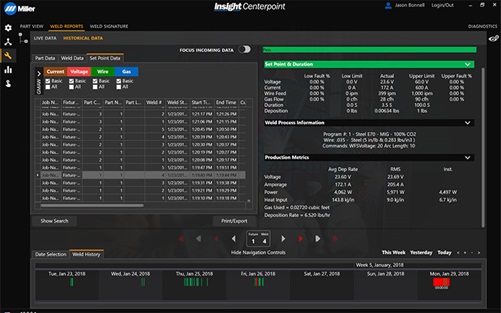

Insight Centerpoint is integrated into Miller Continuum™ and Deltaweld® power systems. It is an on-premises application that can integrate with enterprise IIoT solutions and scale to meet and operations needs.

Insight Centerpoint allows you to:

- Reduce training time. A complex weld sequence can require a lot of training time. Insight Centerpoint helps reduce training time by guiding welders through a weld sequence in real time. It also prompts operators to perform pre- and post-weld activities required to build the part.

- Ensure quality welds. Out-of-parameter welds create rework if they aren’t captured early in the weld cycle. Insight Centerpoint can monitor every parameter of every weld, which helps operations contain weld defects early and provides more control of the weld operation.

- Reduce costs. Missed or defective welds that aren’t detected early in the process are more costly to fix later. Insight Centerpoint alerts welders if a weld is missed or if a weld is outside of acceptable parameters, allowing it to be corrected more efficiently and cost-effectively.

- Remotely configure content. A user of an engineering station hosting Centerpoint can create and validate part configuration remotely and off line prior to plant floor deployment.

Watch this video to learn more about the benefits of Insight Centerpoint weld data monitoring.