Groove weld vs. fillet weld

In steel erection, completing high-quality welds with as little rework as possible is a critical part of maximizing productivity, along with keeping projects on schedule and within budget.

On structural jobsites, though welders use both fillet and groove welds, fillet welds are the most common. The strength required for the application typically determines when operation should use a more complicated complete joint penetration weld instead of a fillet weld.

Here’s an overview of these two common types of welds on structural jobsites.

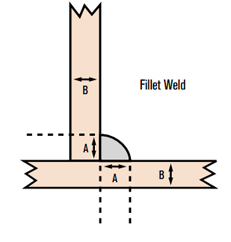

What is a fillet weld?

- The most common and easiest type to produce in structural steel field welding.

- Often used in welded connections with T, lap and corner joint configurations, though it can be found throughout a project.

- Is generally visually inspected and rarely requires additional quality assurance testing.

- Widely used on jobsites, but typical applications using fillet welds include shear tabs, cover plates, bracing connections and column bases, as well as seam and stitch welds.

Welders can often complete these faster and do more of them compared to more difficult groove welds.